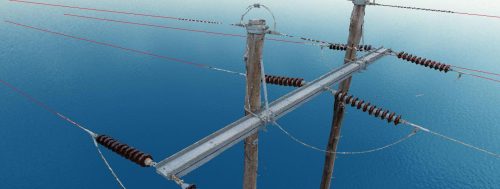

Improved safety: By using drones instead of traditional methods such as climbing towers or ladders, AUAV inspections greatly reduce the risk of injury while still providing accurate data collection results. This ensures that technicians stay safe while performing their duties, reducing costs associated with injuries while inspecting high-voltage lines or equipment.

Cost savings: Drones require less manpower than traditional inspection methods, meaning fewer technicians are needed for a given job—saving time and money for the organization or business conducting the inspection work. Additionally, since inspections can be done remotely and quickly thanks to AUAV’s technology and software suite, businesses may save even more by avoiding potential downtime due to unplanned maintenance needs or repairs related to outdated infrastructure issues spotted during manual inspections.

Reliable results: AUAV has developed sophisticated algorithms that allow its drones to identify problems with power lines or equipment reliably without human intervention—eliminating costly mistakes caused by manual inspections performed incorrectly or incompletely due to fatigue or other factors affecting human judgement capabilities over extended periods of time in demanding conditions such as outdoors on exposed electricity towers and substations where temperatures often vary widely throughout the day.